As the global demand for clean energy continues to surge, the infrastructure required to support it is evolving rapidly. At the heart of this transition lies a critical component—power cable engineering and maintenance. Whether in offshore wind farms, interconnectors, or coastal transmission systems, ensuring the reliability and resilience of power cables is fundamental to the success of energy networks.

With the growing complexity of offshore and subsea installations, innovation in power cable engineering and maintenance is no longer optional—it’s essential. This blog explores the latest technologies, methods, and industry trends reshaping how power cables are designed, installed, monitored, and maintained, especially in the context of forums like the Offshore Transmission Conference.

Why Power Cable Engineering and Maintenance Matters

Power cables—especially those deployed offshore—operate in some of the most hostile environments imaginable. They must withstand pressure, corrosion, movement, temperature variations, and more, all while ensuring uninterrupted power flow over long distances. Failures can be catastrophic, both financially and environmentally, making robust power cable engineering and maintenance strategies indispensable.

Proper cable management and timely interventions can extend the lifespan of these high-value assets, minimize downtime, and protect return on investment (ROI). In today’s energy landscape, innovation in this space is more critical than ever.

Key Innovations Transforming the Industry

1. Digital Twin Technology for Real-Time Monitoring

One of the most impactful technologies in recent years is the digital twin—a virtual replica of a physical system. In power cable engineering and maintenance, digital twins allow operators to simulate conditions, predict faults, and model the effects of cable wear and tear in real time.

By integrating digital twins with environmental data, stress analysis, and operational load conditions, asset managers can forecast potential failures before they occur, reducing unexpected outages and enabling more strategic planning.

2. Smart Cable Monitoring with IoT Sensors

The integration of IoT (Internet of Things) in cable networks allows for real-time monitoring of parameters such as temperature, moisture ingress, voltage fluctuations, and mechanical strain. These smart sensors send data to cloud platforms where AI-driven analytics interpret trends and send alerts when maintenance is required.

This predictive maintenance approach is gradually replacing traditional inspection methods and becoming a hot topic in events like the Offshore Transmission Conference.

3. Advanced Subsea Cable Materials and Coatings

With growing offshore installations, cables are now being engineered using corrosion-resistant materials, UV-stable sheathing, and self-healing insulation layers. These innovations reduce maintenance frequency and offer better resilience against environmental factors like biofouling, sediment movement, and marine life interaction.

Developments in composite materials also offer better mechanical strength and lighter weight, making installation faster and more cost-effective.

4. Autonomous Inspection and Repair Technologies

Innovative robotics and autonomous vehicles are now being used to inspect and repair offshore power cables. Remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) equipped with high-definition cameras and sensors can perform regular inspections without divers or large vessels.

Some systems can even perform automated fault localization and repair, significantly reducing response time during emergencies.

5. AI-Driven Predictive Analytics

Artificial intelligence (AI) and machine learning (ML) models are increasingly being applied to large datasets from offshore and subsea cable operations. These tools identify failure patterns, evaluate risk, and suggest optimal maintenance intervals. By leveraging AI, engineers can shift from reactive to predictive maintenance strategies, improving asset reliability and minimizing costs.

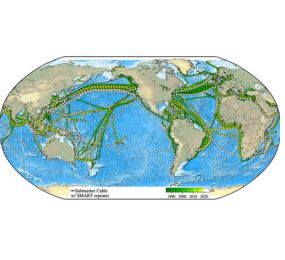

Offshore Transmission and the Growing Need for Innovation

The rise of offshore wind and interconnector projects across Europe, Asia, and the Americas is driving the demand for scalable, reliable, and cost-efficient transmission solutions. As showcased in events like the Offshore Transmission Conference, the spotlight is firmly on technologies that enhance the performance and longevity of power cables.

Offshore cables are especially susceptible to seabed shifts, tidal currents, fishing activity, and installation damage. As such, innovation in power cable engineering and maintenance isn’t just a technical improvement—it’s a necessity for energy security.

Benefits of Modern Cable Maintenance Approaches

Innovative approaches to power cable engineering and maintenance offer numerous advantages, including:

- Reduced Downtime: Predictive monitoring helps prevent sudden failures.

- Extended Cable Lifespan: Improved materials and smart diagnostics enable longer service intervals.

- Lower Maintenance Costs: Targeted interventions reduce unnecessary manual inspections.

- Enhanced Safety: Remote and autonomous systems minimize human exposure in hazardous environments.

- Optimized Performance: Data-driven strategies ensure cables operate at peak efficiency.

Case Study: Offshore Wind Project in the North Sea

A leading European offshore wind developer recently upgraded their power cable network using IoT-enabled smart cables and AI-driven analytics. The system continuously monitored real-time stress and temperature data, predicting degradation patterns well in advance.

As a result, the team avoided two potentially catastrophic failures and optimized their maintenance schedule, reducing costs by 22% over two years. This approach, discussed at the recent Offshore Transmission Conference, is now considered a best practice in the sector.

Looking Ahead: What’s Next?

As the energy transition accelerates, we can expect even greater integration of AI, automation, and resilient design in power cable engineering and maintenance. Future trends may include:

- AI-powered risk scoring for all cables

- Fully autonomous cable repair drones

- Integration with offshore wind energy storage systems

- Blockchain-enabled cable traceability and lifecycle management

Staying ahead in this rapidly evolving field requires continuous learning, collaboration, and participation in industry-leading forums such as the Offshore Transmission Conference.

Conclusion

The success of the global energy transition is closely tied to how well we can design, install, and maintain the critical infrastructure beneath the surface—especially power cables. Through innovation in power cable engineering and maintenance, we are building smarter, stronger, and more resilient energy networks.

As stakeholders prepare for a future powered by offshore wind and marine renewables, adopting these cutting-edge technologies will not just be an advantage—it will be essential.