The complexity in cable design is a very crucial matter in the Cable industry as Cables are built with different factors in play such as Cables are built to withstand natural and man-made dynamic forces witnessed during installation, operation, and decommissioning from the marine environment. Any error in cable design poses a huge impact on the entire System as it can put the whole system on hold till it is repaired so therefore the necessity of best practices when designing a cable is of paramount importance.

The type of power cable used in the installation of floating offshore wind farms is practically not the same used in both offshore fixed-bottom wind farms and onshore wind farms.

Conventional power cables cannot just be laced on the seafloor due to wave currents and other activities but they can be buried under the seabed simply by applying trenches on it for proper protection but this isn't so with power cables should in Floating offshore wind turbines as it can cause too much tension and pressure on the cable, which could affect its stability. However, the cables are being kept on the seabed with protective layers to protect them. Moreso, the protective layers used to depend on the water density. For instance, if the installation is done in shallow or deep water.

Cable Design

Cables are designed to be able to maintain special needs or roles. A lot of brainstorming is done when designing a particular cable so as to fit in the specific purpose it is built for. For instance, the technical requirements such as mechanical engineering and electrical works are different in most cables. It is worthy to note that all Cables must be able to withstand tension load levels like high currents and voltage inflow. Before cables are designed, There are factors needed to be considered such as the type of core to be used, the electric current, the type of conductor, and the insulating material to use.

Functional requirements

A subsea cable used for the Cable laying for floating offshore wind turbines must be able to stand firm even under harsh conditions perceived from the marine environment such as:

-

Movements at the seabed- The power cable needs to be proactive against vertical and horizontal movements in the seabed area as if not considered will definitely damage the Cable in general.

-

Changes in loading- Rapid changes occur in the tension load of Cables during loading like when they are connected to the floating offshore wind turbine. It could damage the cable if precautions were not taken and handled well.

-

Wave currents - Ocean currents are one of the major challenges witnessed in most Offshore activities as they tend to cause cable failures and all, so cables used in floating offshore wind farms are usually made to be resistant to currents.

The firmness of the cable used in the offshore wind must meet the following functional requirements; Stand firm against dynamic loads, normal operational loads, extreme loads such as volcanoes, hurricanes, storms, and others, installation conditions like tensions, from wave, wind, ocean currents as well as other environmental conditions.

Let's Discuss the Cable Core, Can we?

The cable core is designed to be flexible so as to contain sufficient electrical current and mechanical power with the least amount of copper and steel in the cable. In a power cable, the main prerequisites are efficient electrical current, enough tensile strength, and durability.

The outermost layer is normally enveloped with an insulating material such as polyethylene so as to guard it against corrosion. The innermost layer is usually covered with stranding wires made of either copper or aluminum so as to increase its tensile strength. notably, the innermost layer covers about 90% of the total Cable weight.

Typically, a dynamic cable core design requires brainstorming a perfect process in which all its components can be able to work together during operation to achieve the specific reason it is created for. Bear in mind that any change in the design has catastrophic effects which are costly to manage and repair.

In conclusion, the Floating offshore wind market provides a lot of opportunities for the European cable industry and beyond as it is practiced due to its high energy performance, lower risk, clear cost, and reliability.

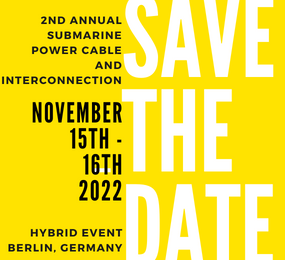

Find out more and how to navigate through so as to run a blossoming project exclusively on the upcoming 2nd Annual Submarine Power Cable and Interconnection Forum.

Come and Interact with other key industry experts!

To request the agenda please send the request to Leadvent Group via email.

For more information and group participation, contact us: [email protected]

Follow us on social media with the event hashtag #SUBCIF22